Hot Sale Highway Guardrail Machine

This machine is the specifical forming equipment for producing the expressway guardrail.The complete machine adapts the cold forming,cold punching,automatic strack.The guardrail plate machine uses archways to increase the firmness of the machine, uses gearbox transmission to make the machine run more stable, and the products are used in various guardrails, highway guardrails, animal husbandry farm guardrails, etc.

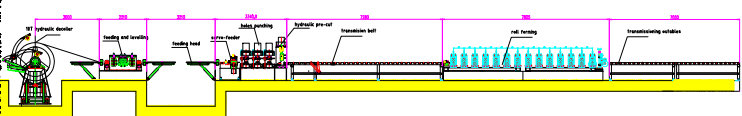

Coil car→hydraulic De-coiler→shovel head,feeding,guiding→9 rolls leveling→servo feeder→holes punching No1,2.3 →hydraulic pre-cut →motorized transmissioning table→roll forming→ auto-stacker

We adopt forged iron stands structure and gearbox drive ( see the picture below) and I beam as base structure and the surface of the machine frame is milled by the CNC center to guarantee the flatness

Forming stands :19 forming stands

Motor power:55kw made in china

Rolled material thickness:2.5-4.0mm HR,GI and black steel

The diameter of the shaft: 105mm

Material of the shaft:40Cr fine processment

Rollers material: SKD-11 l,quenching treatment:HRC60° .chromed on the rollers surface,chrome layer 0.05mm

Driving system:gearbox drive with joint coupling with each stands

Line speed:15m/min

Finished length precision:±1.5mm/10m

Finished straightness precision: ±1.5 degree /10m

Line will be painted industrial blue or green color as picture below or the color provided from the Buyer

The user just just needs to take off the the last 3 stands to form 2 wave guardrails or add the last 3 stands to form 3 waves guardrails .

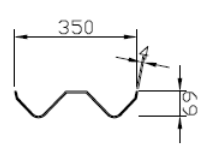

Product width: 350mm/460mm

Product height: 69mm

Product length: 4330mm

Product tolerance:4320mm±1.5mm

Space requirement: Length 45mxWidth 5m xHeight 3m

Finished products: 2 waves and 3 waves guardrail forming machine with 2.5-4mm with holes punching

Raw material request:Q235Mpa hot rolled steel ,black steel or galvanized steel

Material thickness:2.5mm-4mm

Whole line working speed:max15m/min( 3 pcs x4320mm per min

Total power:about 100kw

Input direction: left to right direction

|

NO. |

Name |

QTY |

Remark |

|

1 |

10T Coil car and 10T hydraulic decoiler |

1

1 |

1)Max 10T 2)Hydraulic inner expansion,expansion range:460-520mm.outer dia max1900mm 3)Coil width:max 800mm 4)Drive Motor:7.5kw 5)Hydraulic station motor:4kw |

|

3 |

Shovel head,guiding ,feeding Leveling |

1 set |

1) 9 rolls leveling(4+5rolls) 2)Leveling rolls dia 90mm 3)Leveling motor:5.5kw |

|

4 |

Servo-feeder system |

1 set |

1)Yaskawa servo-feeder 2)3kw plus reducer 3)PLC control cabinet |

|

5 |

Holes punching |

3 sets |

1)We adopt 4 column hydraulic press to punch the holes. 2)Hydraulic punching power:22kw 3)Mould material Cr12Mov,HR58-62 4)Mould qty: 3 sets

|

|

6 |

cutting system |

1 set |

1)We will use hydraulic pre-cut 2)Cutting blade material:Cr12Mov,HRC58-62 3)Cutting power:30kw |

|

7 |

Motorized transmissioning belt |

1 set |

1) transmissioning belt length: 7m 2) Motor:2-1.5kw |

|

8 |

Roll forming machine |

1 set |

1)heavy-stands structure with gearbox chain drive 2)19 forming stands 3)44KW motor made in China 4)Rollers materials:SKD-11 HRC60 5)Shaft diameter:105mm |

|

9 |

Motorized transmissioning table |

7m |

1)Steel frame with Rollers 2)Max length:7m 3)Motor:2-3kw |

|

10 |

Electric control panel |

1 set |

1)1 set control panel for main forming machine 2)Siemens PlC made in Germany 3)Omron encoder made in Japan 4)Yaskawa inverter made in Japan 5) 1 set of control cabinet for servo-feeder |

|

11 |

Hydraulic system |

1 set |

1)1 set of hydraulic station for main forming machine cutting and holes punching 3)1 set of hydraulic station for hydraulic decoiler

|

|

12 |

Cooling system |

|

Water cooling system to be added and the whole water can be circulated in a closed pipeline. |

Fill out the form to contact us, We promise to respond to you quickly.